They hold a large market share in the software industry, valued at $389.86 billion in 2020. Your frame will be simpler and part alignment will be more accurate.CAD or computer-aided design software programs have replaced manual drafting. Just enter the features of the tube in the CAD and obtain the right bending-cut. Save time, eliminate fixturing, gain efficiency!ĭoing lots of test cuts and adjustments are thing of the past. Improves coupling rigidity, maintains accurate joint position, and simplifies weld fixturing.Ĭhoose which tubes to connect and let the system suggest an optimal solution, that you can customise later. New “tooth” style joint - parametric and compatible with all shaped tubes - for even easier joining of two tubes. You can even improve the results by inserting one of the many available interlocking joint solutions.

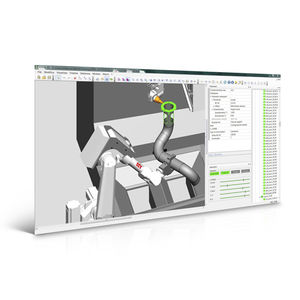

Joints and intersections are solved by ARTUBE. It's that simple to create the programs you need to make your tube frame and chassis design. You can also edit, add or remove features from the imported drawing, change tube size or shape, adjust radii or thickness, without opening the original drawing file or ever exiting from ARTUBE.ĭraw the outline (wireframe) of the structure and then assign the tube dimensions.

Part models created with other CADs and imported in ARTUBE are transformed into native models. Process all formats: STEP, IGES, XT and even IFC. Import 3D models created using external CAD systems with a single click.

The difference that no-one else can give youģD CAD/CAM graphic software for designing and programming tubular partsĪll 3D graphic CAD/CAM dedicated to tube processing

0 kommentar(er)

0 kommentar(er)